3D Printed Circuit Boards: Future Prospects

3D Printed Circuit Boards it is transforming the traditional electronics manufacturing landscape at an astonishing pace, ushering in unprecedented changes for the industry

1.Breakthrough in 3D Printed Circuit Boards Technology

Traditional circuit board manufacturing relies on complex etching processes, which require multiple processes such as photolithography, development, etching, and drilling, which are not only time-consuming and labor-intensive, but also have low material utilization.

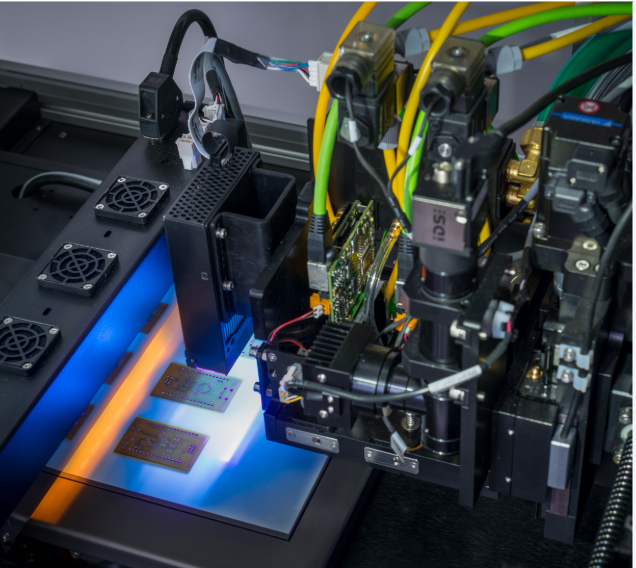

The introduction of 3D printing technology, through layer by layer stacking, directly deposits conductive materials on the substrate, achieving a leap from two-dimensional plane to three-dimensional.

Taking metal 3D printing as an example, laser selective melting (SLM) technology can accurately control the melting and solidification of metal powder, forming complex circuit structures.

This method not only avoids material waste in traditional etching processes, but also integrates components such as sensors and antennas on circuit boards, achieving diversified functions.

2.Challenges and Opportunities

Despite the promising prospects of 3D printed circuit board technology, it still faces many challenges.

Firstly, the conductivity and stability of printing materials need to be further improved.

At present, the resistivity of most 3D printed conductive materials is still higher than that of traditional copper foils, which limits their application in high-speed circuits.

Secondly, the contradiction between printing accuracy and speed has not been fully resolve. High precision printing often requires longer printing time, while fast printing may sacrifice the quality of the circuit.

However, with the continuous advancement of technology, these challenges are gradually being overcome.

For example, the development of new nano conductive materials has significantly improved the conductivity of 3D printed circuits.

Meanwhile, the application of multi print head technology has made parallel printing possible, greatly improving production efficiency.

3.Future Prospects

3D printed circuit board technology is not only a manufacturing method, but also a liberation of creativity. Through 3D printing, designers can break free from the limitations of traditional manufacturing processes and freely design complex circuit structures.

For example, by using topology optimization algorithms, circuit board structures that are lightweight and have the best mechanical performance will be design.

In addition, 3D printing technology will also promote personalized customization of electronic products. Consumers can customize electronic products with unique appearance and functionality according to their own needs. This shift from standardized production to personalized customization will greatly enrich the market for electronic products.