PCB Assemble Medical devices

Medical devices PCBA demand flawless performance, and at their core lies the Printed Circuit Board (PCB). Suga medical PCB Assembly (PCBA) services integrate cutting-edge technology with rigorous quality assurance to meet the stringent standards of the medical device industry.

With ISO 13485 certification, Suga ensures full compliance with medical industry standards. Our PCBA products are widely applicated: Class III Medical Devices, Ultrasound systems, Patient monitoring equipment, Medical imaging devices, Diagnostic instruments CT scanners, surgical lights…

Suga Comprehensive Medical devices PCBA Manufacturing Capabilities

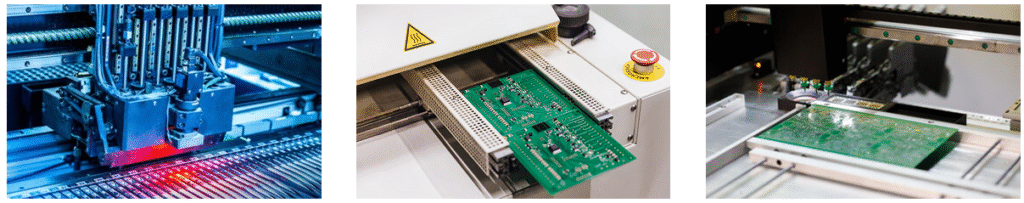

Advanced Assembly Capabilities

- Surface Mount Technology (SMT), Through-Hole Technology (THT), hybrid technology

- Ultra-fine pitch placement (up to 12 mil)

- Rigid and flex PCBs, double-sided PCBs, flexible circuits, multilayer PCB (up to 38 layers)

- Complex RF electro-mechanical medical PCB assemblies

Comprehensive Component Handling

- Package sizes: 01005 (0201), BGA, µBGA, 55 mm² CSP

- Component types: Through-hole, SMT, BGA, QFN, and mixed technologies

Precision Medical PCB Manufacturing Processes

- N₂-enabled reflow soldering for superior quality

- Automated conformal coating (acrylic, parylene, silicone, and polyurethane)

- Potting and encapsulation for enhanced durability

- No-clean solder and DI water wash processes

- RTV glue dispensing, laser marking, and de-panelization

Customized Medical PCB Assembly Solutions

- Support for prototypes, high-mix low-volume batches, and high-volume runs

- Board sizes of up to 534 × 610 mm

- No limits on minimum prototyping sizes

Component Lifecycle Management

- Bill of Materials (BOM) optimization

- Component End-of-Life (EOL) management

- Obsolescence solutions

Your Medical Device. Uncompromising Quality, Assured Reliability.

Our approach to fulfilling your stringent reliability needs with complete traceability is as follows:

Operating in accordance with IPC-6012 Class 2 and Class 3 standards, we manufacture standard, advanced, and micro printed circuit boards with precise accuracy. Our high-tier boards are compliant with UL 94 V-0 flammability specifications. The following documents and certifications are available upon request:

- Compliance certification

- Specifications for all materials used

- Report from the initial product inspection

- Copy of the reflow soldering temperature profile (provided with the initial sample)

- Requirements for photographic documentation

- Adherence to IPC J-STD-001E standards

- Documentation for every calibrated instrument utilized in production

- Report from automated optical inspection or manual visual assessment

- Results from flying probe or in-circuit electrical testing

- Report on ionic contamination levels and cleanliness

We adhere to the following industry standards, which enable us to produce superior and dependable medical-grade circuit boards for the healthcare and medical technology sectors:

Comprehensive Electrical Testing for Medical-Grade PCBs

We do not compromise on quality and adhere to the strict manufacturing standards required for medical circuit boards—this involves continuous testing throughout the production stages, including cross-sectional analysis, automated optical inspection (AOI), BGA X-ray examination, flying probe testing, and other electrical evaluations.

Integrated Fabrication and Medical devices PCBA

Communication gaps between separate fabrication and assembly providers often lead to delivery delays and board defects. A PCB manufacturer that does not manage assembly will not perform design-for-assembly (DFA) reviews to verify that your board can be correctly assembled. Having a single responsible supplier ensures accountability.

How to Obtain a Quote for Medical devices PCBA

We can conduct DFM/DFA analysis on your behalf and return a detailed report. You may securely submit your files through our website.

To provide an accurate quotation, we need the following details:

- Design files in Gerber, ODB++, or IPC-2581 format

- A bill of materials (BOM), if assembly is required

- Order quantity

- Required turnaround time

Let’s Create Perfect PCBAs for Your Medical Device!

Begin an online quotation for circuit boards that satisfy your medical-grade specifications.