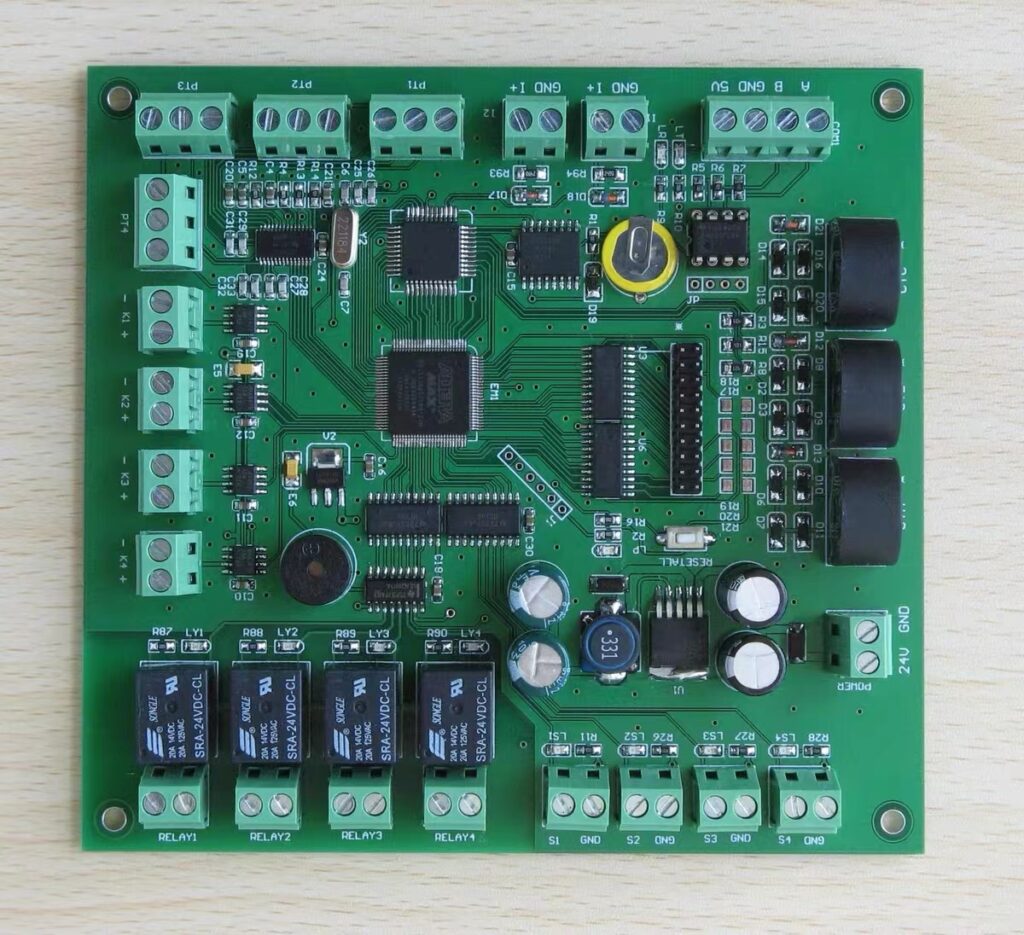

PCB Mounting

PCB mounting is a core process in electronic product manufacturing. And its quality directly determines the performance and reliability of circuit boards. To ensure smooth production, the following key aspects require special attention.

Incoming Material Control Is The Foundation

We must inspect the Components and PCBs strictly before mounting. For components, it is essential to verify that their model, specifications match the BOM list. And to check for moisture exposure, particularly for MSDs (Moisture-Sensitive Devices), which we should bake them if necessary. For PCB boards, we should inspect the pads for oxidation and any warping or deformation.

Process Parameter Settings Are Critical To PCB Mounting

Solder paste printing is the first step, where we must align the stencil precisely with the pads. After printing, we should fully filled the solder paste on the pads, and make them well-shaped and uniform in thickness. The accuracy of the mounter directly determines component placement and requires regular calibration. We must check nozzle cleanliness and vacuum pressure must also be frequently to prevent component flying or tombstoning. The reflow soldering temperature profile is the core factor determining soldering success. We must set it carefully according to the solder paste specifications and board component layout to ensure the temperature and duration during preheating, reflow, and cooling stages are optimal, avoiding cold solder joints, bridging, or component thermal damage.

Environment and Electrostatic Protection Cannot Be Overlooked

The production workshop must maintain constant temperature, constant humidity. And cleanliness to prevent dust from affecting soldering quality or causing short circuits. We must conduct all operations within an electrostatic discharge (ESD) protection system and keep components away from damage or failing due to electrostatic discharge.

Rigorous Quality Inspection Is Essential

In addition to in-line AOI (Automated Optical Inspection) and X-Ray inspection, first-article inspection, in-process sampling. And finished product functional testing are all indispensable to promptly identify issues and facilitate traceability and adjustments.

In summary, only through stringent material control, precise process optimization, reliable environmental management. And comprehensive quality monitoring can high-quality PCBA be efficiently produced, laying a solid foundation for the stability and reliability of electronic products.