PCB Assembly Manufacturer

- 20+ Years Experience on Electronic Manufacturing Services

Following the standards of IATF,ISO,IPC,UL. Online SPI,AOI,X-Ray etc, 99.9% yield of product.

-

PCB Assembly from Rigid, FPC to Rigid-Flex board with leaded & lead-free solder.

-

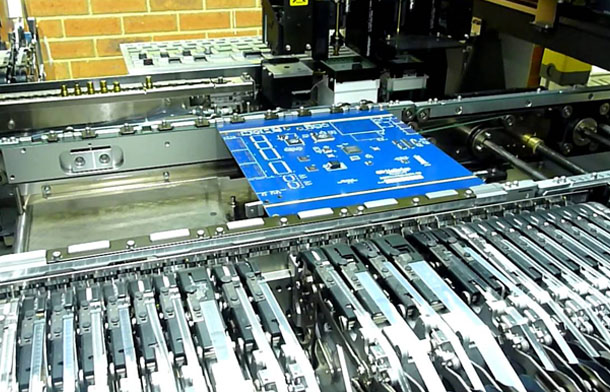

Automatic SMT assembly 18 lines, 6 DIP and finished product assembly lines.

-

8-48 hours delivery time when components are ready.

-

Full range of reliable suppliers for components.

-

7/24 active sales & technical support.

PCB Assembly Manufacturing Solutions

PCB Assembly Process and Quality Control Overview

PCB Assembly (PCBA) is the critical manufacturing process of accurately assembling electronic components onto printed circuit boards. It involves a rigorous procedure with multiple quality control measures to ensure reliability.1. Core Process Flow

Firstly, Material Preparation and DFM Validation

Components are procured based on the BOM list. Becaused stringent inspection of incoming material quality (such as PCB flatness, IC model consistency) was taken, so second-hand or counterfeit materials are elimated. A Design for Manufacturability (DFM) analysis is conducted to optimize PCB layout (e.g., avoiding high component obstructions for maintenance points, preventing high-frequency interference), preemptively addressing potential process risks.Secondly, Solder Paste Printing and Placement

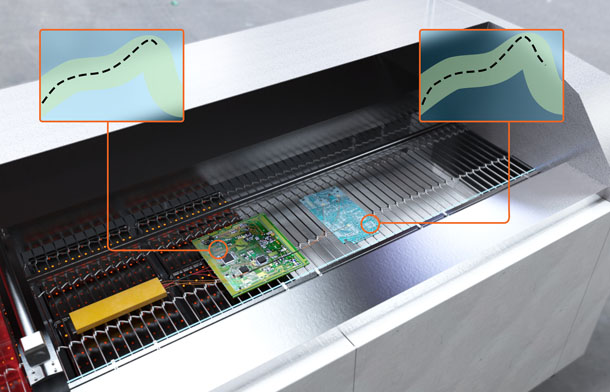

A laser stencil is used to precisely apply solder paste, with hole size control (such as U-shaped holes) ensuring even pad coverage. High-speed pick-and-place machines achieve micron-level precision in component placement, minimizing human error.And Finally, Reflow Soldering and Through-hole Processing

The reflow soldering oven temperature curve is strictly controlled to ensure proper solder paste melting and reliable electrical connections. Custom molds are used during wave soldering for through-hole components to optimize yield.2. Key Quality Control Measures for PCB Assembly

Comprehensive Inspection Techniques

AOI (Automated Optical Inspection): Multi-angle scanning of solder joints quickly identifies misalignment and cold solder joints. X-ray inspection: Provides a view of hidden solder joints like those under BGAs, detecting bridging and voids. ICT/FCT Testing: Power-on verification of circuit conductivity and functional performance.Standardization of Process Parameters

Standardization of solder paste composition, reflow soldering temperature zones, and utilizing Statistical Process Control (SPC) reduce the fluctuations.Final Reliability Verification

After PCB assembly, conducting burn-in tests, temperature and humidity cycles, drop tests, etc., simulate stability under extreme conditions.3. Quality Control Value Loop

From raw material inspection to process parameter monitoring and end-of-line testing, Suga establised a 'prevention-monitor-correct' system PCB assembly. Long-term stability of high-density PCBA in complex operating conditions can be ensured, such as smartphones. Suga Tech is taking all the above procedures strictly in PCB assemebly, so that our customers are stable and willing to expand business. With this regarding, though Suga is not your best choice but your top rank choice, send inquiry now.

- Turn times as short as 24 hours

- 1 to 100,000 units

- Class II Inspection standard and Class III Inspection available

- 100% on-time guarantee

- DFM support

- Lead free (RoHS) options

- SMT and thru-hole capabilities

- All SMT machine placed

- AOI (Automated Optical Inspection

- Lead-free RoHS Certification and ITAR compliance screen available

-

Program Design

-

Process Capability

-

Part supply flexible

-

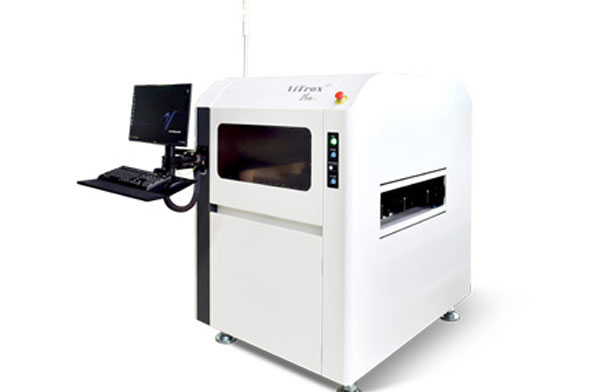

Equipment Exhibition

Suga Tech offers one-stop services for all types of PCBs fabrication and assembly, from component procurement to functional testing and package completion.

PCB Assembly Capability

| Assembly type | SMT, THT&Hybrid, single or double side placement, 0105 coponents |

| Stencils | Offer Laser-cut stainless steel stencil. |

| Solder type | Offer both lead&lead-free (RoHS Compliant) assembly services. |

| Board type | Rigid board, flex board&rigid-flex board. |

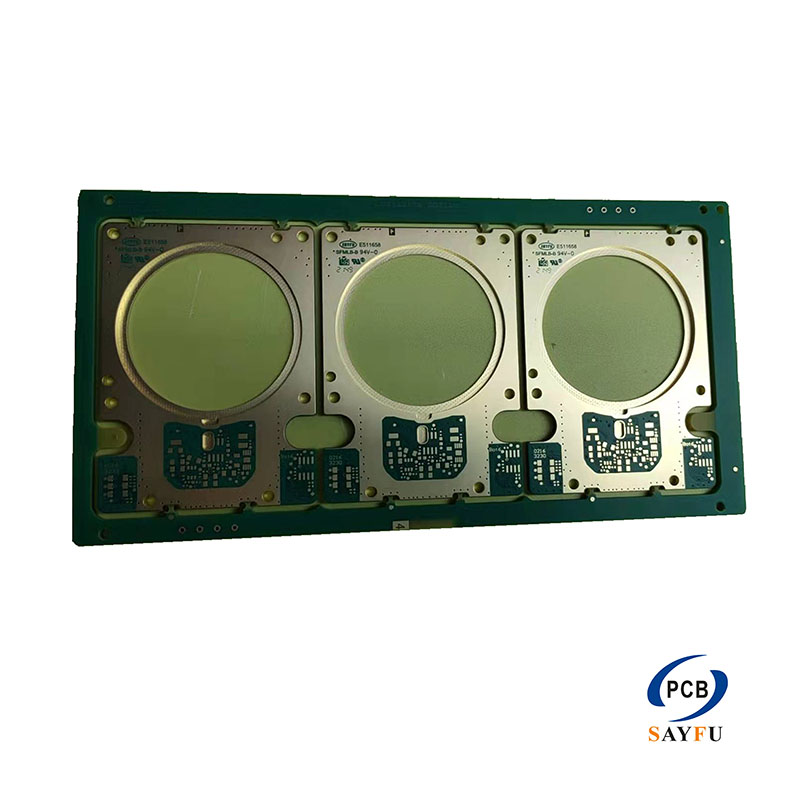

| PCB or Panel Size | Min board size of 10*10mm, will be panelized to suit the SMT machine |

| PCB or Panel Size | Max board size of 330*530. |

| Board shape | No restrictions for rectangular, Circular and any Odd Shapes, will adjust the panelize for better placement. |

| Components | Passive components as small as 0105,0201,0402 |

Part supply flexible

| Turn-key | We source all components for you from authorized components suppliers or distributors. |

| Partial Turn-key | Customer offer partial of components as they prefer and we will source the rest as required. |

| Consigned | Components can be supplied by the customer. We accept parts in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. |

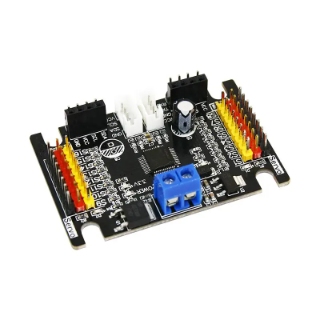

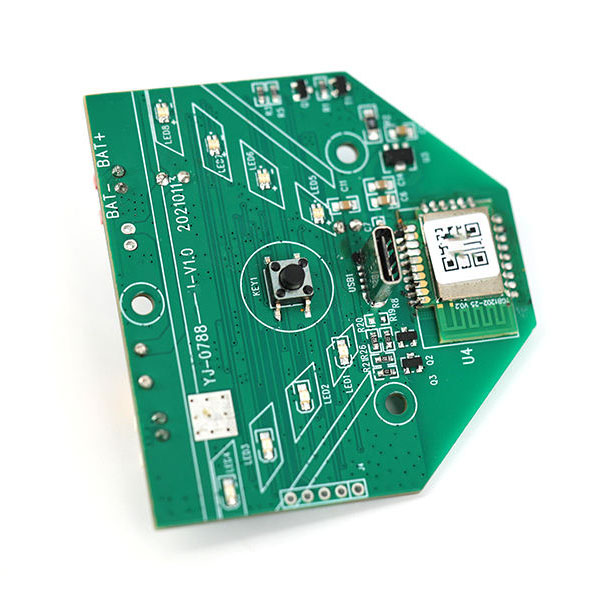

PCB&PCBA Products Show

PCB Assembly Application in Multiple Industries

As the core carrier of electronic systems, PCB assembly technology demonstrates its crucial value in the military, medical, communication, and artificial intelligence fields:

Military Field: It is applied in radar systems, missile guidance, and satellite communication equipment. High-frequency PCBs ensure high-speed signal transmission and anti-interference capabilities, supporting real-time battlefield information processing.

Medical Field: Implantable devices (such as cardiac pacemakers and neural stimulators) rely on high-density interconnect (HDI) PCBs to achieve miniaturization and reliability. Imaging equipment such as CT and MRI improves diagnostic accuracy through precision PCBs.

Communication Field: 5G base stations, microwave links, and satellite transceivers use high-frequency PCBs to meet the low-loss requirements of the millimeter-wave band, ensuring high-speed data exchange.

Artificial Intelligence Field: AI servers (such as NVIDIA‘s GPU architecture) rely on high-performance PCBs to support CPU/GPU heterogeneous computing. Through HDI processes and material upgrades, they can handle massive amounts of training data, driving a leap in computing power.

The evolution of PCB Assembly technology is driving the intelligent upgrade of multiple industries and has become the underlying cornerstone of modern technological innovation. Suga Tech has been in the field for more than 20 years, so it has collected high deep knowlodge and technology, with which it has being growing stabler and stronger. Suga tech is your reliable partner in PCB fabrication and assembly.

Bring you better PCB products

Circuit Board Fabrication and PCB Assembly Turnkey Services

PCB Assembly asked questions

What is PCB assembly?

What are the different types of PCB assembly?

Can PCB assembly be automated?

Who performs PCB assembly?

How do I select a PCB assembly manufacturer?

Can PCBs be repaired or modified after assembly?

What is surface mount technology (SMT)?

What is the difference between through-hole and surface mount technology

Why Choose Us?

Suga has been providing high-quality PCBs with fast turnaround times and high customer satisfaction since 2002. With over ten years of industry experience, we are a leading PCB manufacturer and PCB assembly company based in China. Based on your ideas or schematic diagram, we can complete the one-stop PCB manufacturing process from design to assembly (Design).

-

Within 24 hours, prototype orders are processed.

-

It usually takes 5-7 working days to complete some PCB prototypes and small-batch manufacturing.

-

A shorter lead time of 48 hours for small batch production and some PCB prototypes.