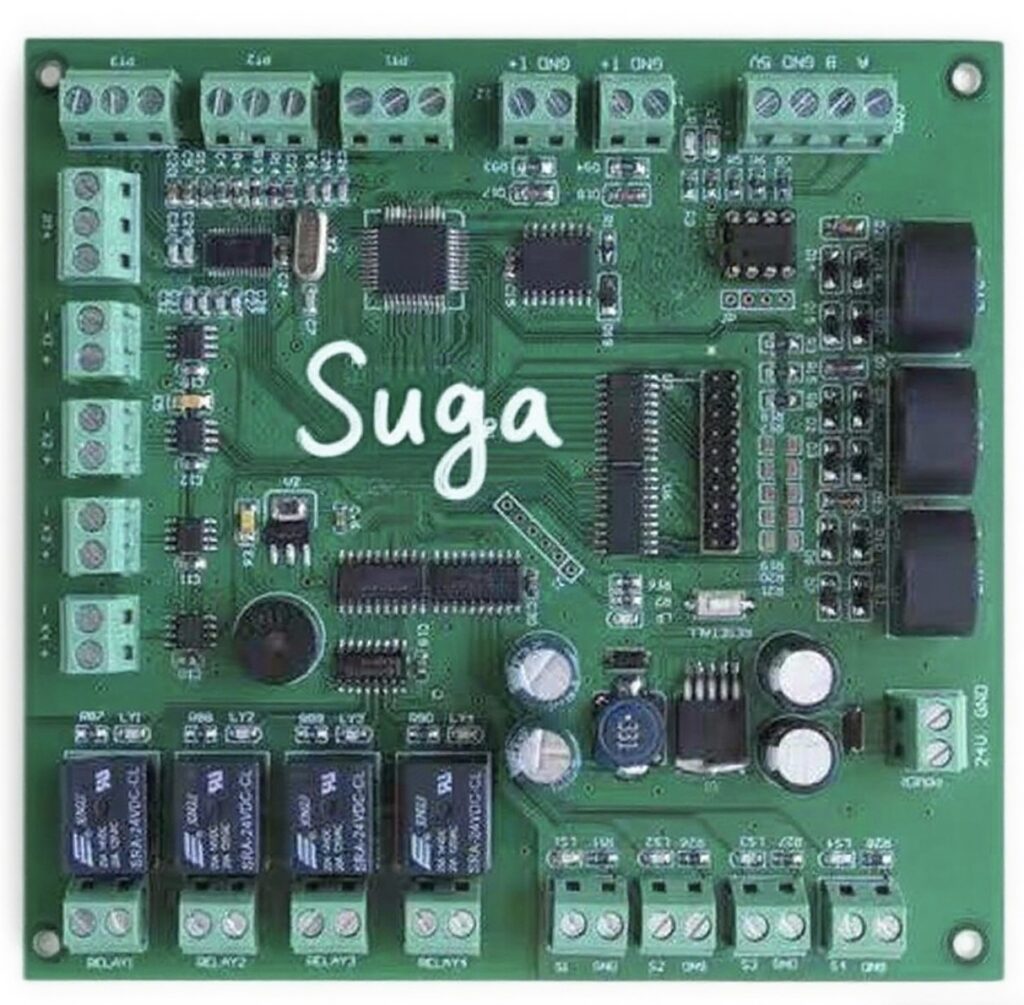

Medical Print circuit assembly

Medical Print circuit assembly’s Special requirements

- Medical Print circuit assembly’s high reliability

–Medical Print circuit assembly need to pass the aging test,Environmental stress test and so on.And Medical equipment (such as monitoring equipment, pacemakers, imaging devices) must be long-term stable operation.

–Medical PCBA must be use Industrial or medical grade components to make sure it can work on the extreme condition

2.Strict regulatory certification

–FDA,ISO13485 Verification is absolutely necessary.

–Must meet the environmental protection requirements such as RoHS and REACH,to avoid the hazardous substance to effect people’s health

3.Miniaturization and high integration

–Portable medical equipment require the PCBA must miniaturization and low power consumption. Need use HDI and FPC technology

4.Anti-interference and signal integrity

–The medical equipment is easy to interference by electromagnetism. So,the PCB layout and shielding design need to be optimized, and EMC tests must be passed.

Medical Print circuit assembly’s Manufacturing Challenges and Solutions

- Clean production environment

–Some Medical Print circuit assembly must proceed in the dust-free plant. To avoid pollution affects performance

2.High-precision welding and inspection

–Use high precision SMT paster,3D SPI,AOI,X-ray inspection to make sure the quality

–The precise packaging methods such as BGA and QFN require strict process control.

3.Long-term supply and traceability

–The life cycle for Medical equipment is very long,need to make sure the components can long-term supply.Additionally, establish a complete traceability system.

4.Three-proof treatment (moisture-proof, anti-corrosion, and anti-bacterial)

–Medical-grade three-proof paint must be applied to PCBA (in order to / to significantly) improve its durability in humid and sterilization environments

Medical Print circuit assembly’s future trend

–AI + Medical Print circuit board assembly :Such as Machine learning optimizes fault detection and enhances yield.

–Wireless medical equipment:Such as Bluetooth/Wi-Fi module integration, supporting remote monitoring

–Biocompatible materials, especially special PCB materials, are ideal for implantable medical devices due to their safety and reliability

Conclusion

Medical Print circuit assembly is the core of medical equipment. Unlike ordinary consumer electronics, it features high reliability, strict certification, and precise manufacturing requirements

Choose the experienced medical PCBA manufacturer, and adhering to standards such as ISO 13485 and FDA. Is the key to ensuring the safety and stability of medical equipment.

Choose Suga ,As a result, you’ll never regret it