IoT PCBA

IoT-focused printed circuit board assemblies refer to custom-designed circuit boards specifically engineered for devices integrated into the Internet of Things framework. Such devices commonly incorporate sensing units, wireless communication components, and embedded processing systems, enabling online connectivity, data acquisition and transmission, as well as the execution of diverse automated tasks.

Primary Applications of PCBA in IoT Devices

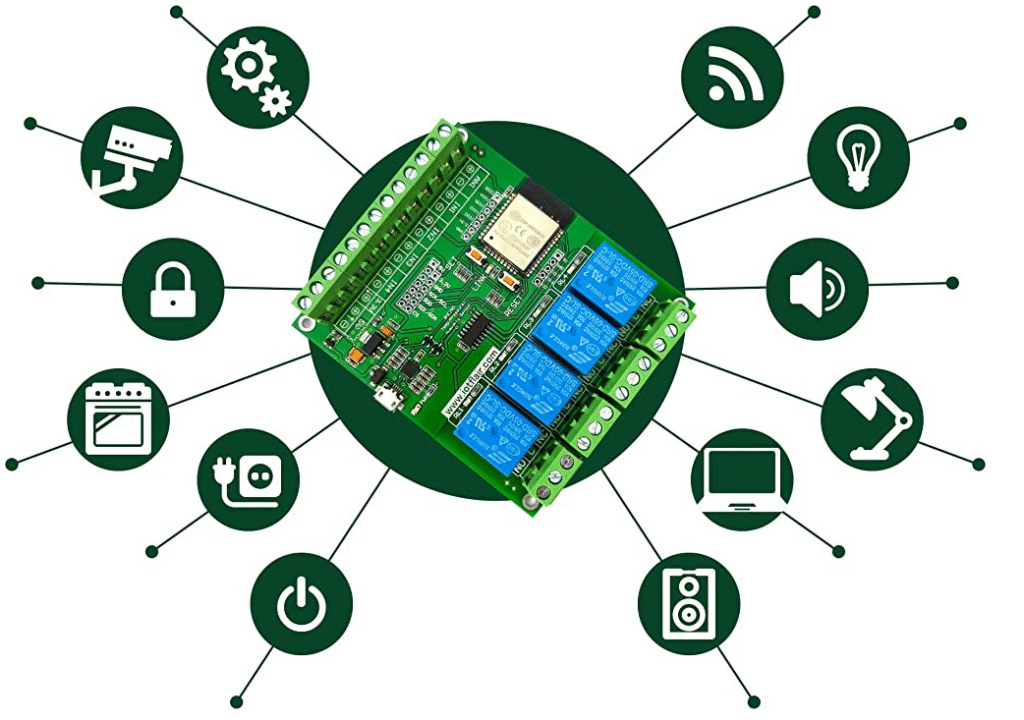

Smart Home Systems

IoT-based home automation products, such as climate controllers, surveillance cameras, intelligent lighting, and electronic locks, rely significantly on advanced printed circuit board assemblies. These products require small-form, energy-saving PCBAs compatible with wireless connectivity standards like Wi-Fi, Zigbee, and Bluetooth. Precise component arrangement and circuit design are vital to reducing physical dimensions and power drain while ensuring uninterrupted communication.

Wearable Technology

Devices like activity monitors, health sensors, and connected wristwatches utilize PCBA to incorporate sensing elements, display units, and wireless communication chips. The miniature design of wearables necessitates specialized circuit boards that are both space-efficient and resilient, able to tolerate regular use and exposure to external conditions. Additionally, optimized power management is a critical design consideration to prolong battery duration for consumers.

Medical IoT Solutions

Within healthcare, IoT devices facilitate remote patient tracking, diagnostic tools, and implantable medical equipment. For instance, internet-connected glucose meters, cardiac rhythm management devices, and pulse monitors depend on trustworthy and secure PCBA implementations. These circuit assemblies must satisfy strict medical equipment regulations, adhering to standards such as ISO 13485 and FDA approval guidelines.

Industrial IoT Implementations

Industrial IoT uses encompass automated manufacturing setups, condition-based maintenance systems, and networked industrial equipment. PCBA in IIoT devices frequently must support tough operational settings, rapid data handling, and dependable wireless links. For factory sensors and control units, the printed circuit board needs to be built to cope with severe conditions including temperature extremes, mechanical vibrations, and contact with contaminants or dampness.

Agricultural IoT Deployments

Agriculture employs IoT technology in automated watering systems, ground moisture detectors, and plant monitoring devices. PCBA used in these applications must be robust, energy-conscious, and capable of enduring environmental variables like humidity changes and thermal variations. Furthermore, IoT equipment in farming often operates in isolated areas, requiring low-energy PCBA architectures to support sustained functionality without frequent maintenance.

In the Internet of Things domain, IoT printed circuit boards are essential in facilitating intelligent, interconnected devices across diverse applications. As IoT devices grow in ubiquity and usage scenarios expand, the demand for dependable, high‑performance IoT circuit boards becomes ever more significant.

Enabling device connectivity: IoT PCBs function as the core infrastructure for linking devices, ensuring smooth communication, information exchange, and coordinated operation among IoT systems.

Collecting and processing data: Through the incorporation of multiple sensors and data‑capture modules, IoT PCBs make it possible to monitor and process environmental, positional, thermal, humidity, pressure, and other real‑time information, laying the groundwork for informed automated decisions.

Remote operation and automation: IoT PCBs deliver remote‑control functionality, allowing users to manage smart‑home setups, industrial equipment, or wearable gadgets via smartphones, computers, or cloud‑based interfaces.

Facilitating big data and analytics: Sophisticated IoT PCBs can manage substantial data streams, supplying analytical platforms to refine processes, forecast maintenance requirements, and improve overall system performance.

Enhancing operational efficiency and quality: In industrial settings, IoT PCBs enable continuous equipment monitoring and data analysis, process automation, and optimization measures—leading to greater productivity, improved output quality, and minimized operational interruptions.

By integrating robust reliability, precise engineering, and advanced printed circuit board technology, IoT PCBs establish the basis for smart, data‑oriented, and highly efficient IoT ecosystems, helping businesses and end‑users realize the complete value of connected devices.

In summary

Suga worked with over 1000 all over the world in the telecom, 3G product, RF, security, industrial, medical and hi-tech industries.

We have no MOQ requirement. Call us or email us today to learn more details.