Intelligent PCB production is widely applied

Intelligent PCB Production: Automation, Digitization, and Intelligence Technologies

一、intelligent PCB production layout

intelligent PCB production

1.EDA software + AI algorithms, automatic layout and routing will achieved, This can helps to reduce human intervention and optimize the circuit performance.

2.3D modeling + digital twin technology, the PCB production process will simulated in a virtual environment, Furthermore, enabling the early detection of design and manufacturing conflicts.

二、intelligent PCB production Material and pre-treatment

1.Automated material to selection

2.Intelligent cut material size,As a result,to Helps to precisely cut the substrate and reduce material waste

三、intelligent PCB production main manufacturing process

1.By using combining laser direct imaging with AI visual positioning,Therefore, the production of the lines has become more highly precise.

2.The CNC drilling machine+machine vision, can automatically identify and locate the holes, achieving high-speed and precise drilling.

3.The automated electroplating line is controlled by the PLC system.To achieve uniform coatings (such as copper, nickel, gold), and to monitor the coating thickness in real time through online detection equipment

4.By replacing traditional screen printing with inkjet printing technology,

high-precision and personalized printing of the solder mask layer and characters can be achieved, supporting small-batch customized production.

四、Test and quality control

1.Automated inspection: AOI、AXI、AI,Therefore, quality issues such as line defects and solder joint will can identified.

2.Traceability system: via RFID or QR code,This enables quick resolution during the later stage of quality traceability.

五、PCB assembly(PCBA)

1.Intelligent SMT:To using a high-speed SMT machine, combined with visual positioning and AI-driven optimization of the soldering path, the assembly efficiency and accuracy significantly to improved.

2.Intelligent welding: To using reflow soldering / wave soldering equipment uses infrared temperature measurement and AI temperature control algorithms to adjust the temperature zone curve in real time, meeting the requirements of different soldering points and reducing false soldering and false welding.

六、Key technical support

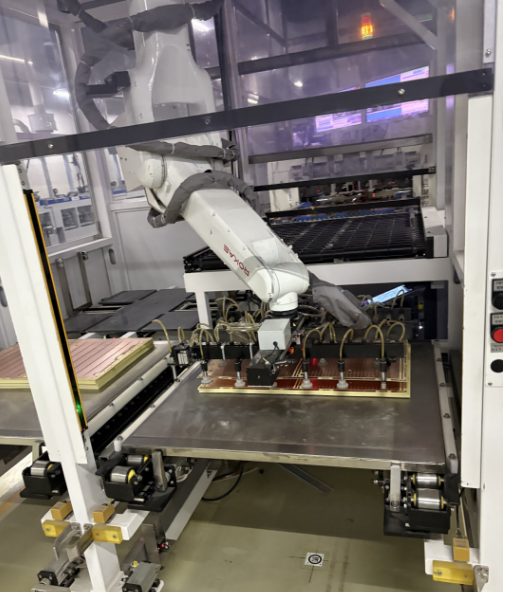

1.Automated production line: AGV (Automated Guided Vehicle) to help automatic material transportation, and robots handle the loading and unloading processes.

2.Data-driven optimization: Collect production data through MES (Manufacturing Execution System).

Furthermore, analyze the process bottlenecks, dynamically optimize the production parameters, and achieve flexible manufacturing.

The core of intelligent PCB production technology lies in “replacing manual labor with machines” and “making decisions based on data”, which can meet the production demands of high precision, high reliability, and small batch, multiple varieties. It is particularly suitable for high-end fields such as automotive electronics, 5G communication, and industrial internet.