How to Choose the Right Manufacturer for Circuit Board Assemble?

Circuit Board Assemble is the core process in electronic product manufacturing. Choosing the right partner is of vital importance as it directly affects the quality, cost and time-to-market of the products. When faced with numerous circuit board assemble factories, enterprises must conduct rigorous evaluations from multiple key dimensions to ensure that their production capacity and service level can meet the requirements of specific projects.

Evaluation of the technical capabilities of Circuit Board Assemble manufacturers

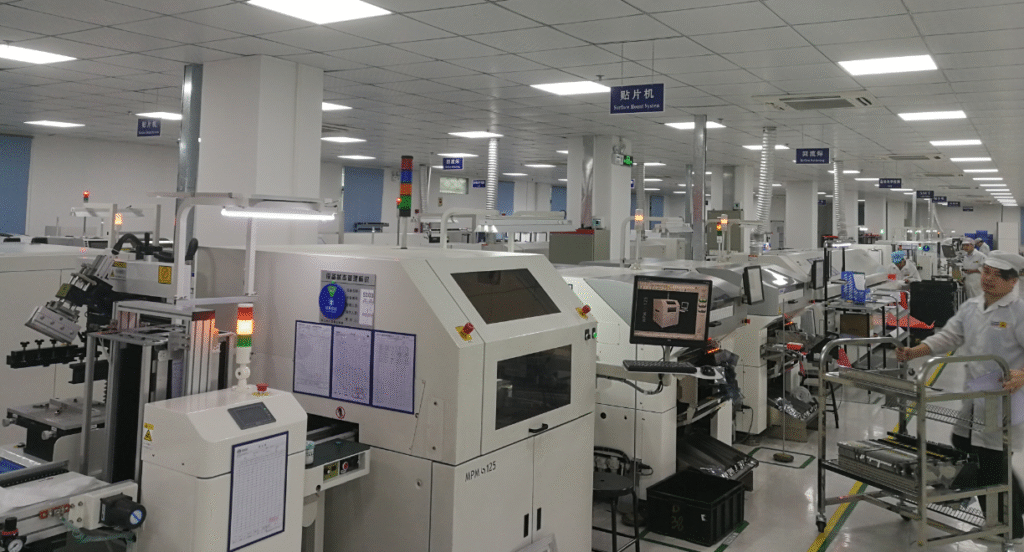

Firstly, a thorough examination of the factory’s technical and equipment capabilities is fundamental. This is not merely about whether the factory possesses basic processes such as surface mount technology (SMT) and through-hole assembly (THT), but also about the sophistication and stability of its equipment. For instance, when it comes to the assembly of circuit boards with high-density and miniaturized components, does the factory have high-precision surface mounters, advanced SPI (solder paste inspection) and AOI (automatic optical inspection) equipment to ensure welding quality? Additionally, the technical capabilities should also extend to the factory’s experience in handling different PCB types (such as rigid boards, flexible boards, and rigid-flex boards), as well as its professional level in dealing with special processes (such as blind vias, BGA repair).

Comprehensively assess the comprehensive capabilities of the partners

The quality control system is the core. Determine whether it has obtained relevant international certifications such as ISO9001, IATF 16949 (for the automotive industry) or ISO13485 (for the medical industry), and understand the specific processes of incoming material inspection (IQC), process quality control (IPQC), and final testing (FQC). Supply chain management capability is also crucial, especially in the case of fluctuating global component supply. A strong supply chain system can ensure stable material supply and prevent production disruptions. Finally, examine its communication efficiency, project response speed, after-sales support, and whether it has the seamless connection capability from small-batch rapid prototyping to large-scale mass production. Transparent pricing models and cooperation terms are also an important part of building a trust relationship.

Summary

In conclusion, choosing the right Circuit Board Assemble factory is a systematic decision-making process. Enterprises should conduct on-site inspections, review qualifications, evaluate past project cases, and carry out small-scale trial production, etc. to comprehensively assess the factory’s overall strength in terms of technology, quality, supply chain, and services. Thus, they can establish a reliable and efficient partnership to ensure the success of the products.