Medical Flex Pcb Assembly

What is FLEX PCB assembly?

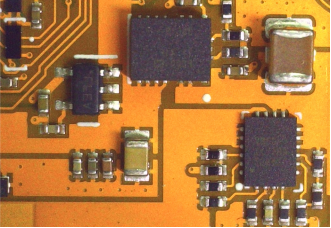

Medical Flex Pcb Assembly refers to the process of welding and installing electronic components onto a flexible circuit board.

Compared to traditional rigid circuit boards, flexible boards can be bent and are lightweight, making them suitable for use in products,

such as mobile phones, wearable devices, and automotive electronics that require compact space or flexible structures.

The assembly quality directly affects the performance and lifespan of these devices.

Key steps in Medical FLEX PCB assembly

Pre-treatment: The flexible board is prone to absorbing moisture. Before assembly, needs to bake remove the moisture to prevent air bubbles from forming during welding. At the same time, a special carrier board should be used to fix the flexible board to prevent it from deforming during processing.

Solder paste printing: Using the appropriate solder paste and scraper, evenly apply the solder paste onto the pads of the flexible board. This step requires precision to avoid excessive or insufficient solder paste.

SMT: Using a soldering machine, place resistors, capacitors, chips and other components accurately onto the corresponding pads. Since the flexible board is relatively soft, we need carefully controll the force and position during soldering.

Reflow soldering: Through the high temperature of the reflow soldering furnace, the solder paste melts and solidifies, firmly bonding the components and the flexible board together. The temperature curve must be appropriate to prevent damage to the flexible board.

The difficulties and advantages

If not handled carefully during processing it will be damag . However, the advantages are also quite obvious. The assembled product can adapt to complex spatial layouts, making the equipment thinner and lighter and the design more flexible. For example, the connection of the screen and the main board of smart watches is often through the assembly of flexible boards to achive.

Overall, FLEX PCB assembly is the key step that enables flexible circuit boards to showcase their advantages. It requires meticulous processes to ensure the reliability of the final product.

As a factory with over 20 years of production experience, we can provide the highest quality service for both conventional FR4 and FPC products. We ensure that quality comes first. If you have any needs, please don’t hesitate to contact us – SUGA