PCB Design

PCB (Printed Circuit Board) design is an essential aspect of modern electronics, and it offers several benefits that make it an attractive option for engineers and designers. Here are some reasons why you might choose Suga Tech:

Chinese PCB Design Steps

Chinese PCB design typically involves the following steps:

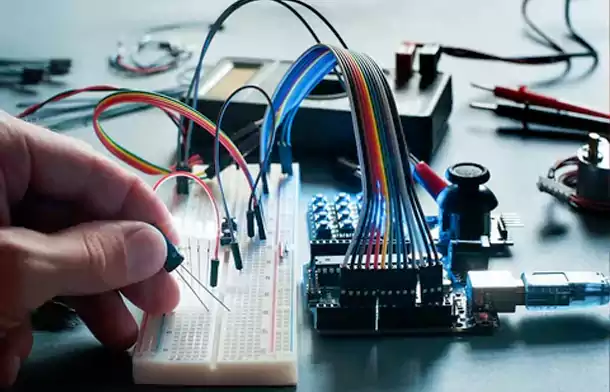

Schematic capture: This involves creating a diagram of the circuit using specialized software. The diagram shows the various components in the circuit, their connections, and the signals that flow between them.

Component selection: Once the schematic is created, the designer selects the components that will be used in the circuit, taking into account factors such as their specifications, availability, and cost.

PCB layout: This involves creating a physical layout of the circuit on the PCB substrate. The designer places the components on the board and creates a pattern of electrical traces that connect them. The layout must take into account factors such as signal integrity, power distribution, and heat dissipation.

Gerber file generation: Once the layout is complete, the designer generates a set of files called Gerber files that specify the details of the circuit board design, including the placement of components, the routing of traces, and any drill holes or cutouts that are required.

PCB fabrication: The Gerber files are sent to a manufacturer, who uses them to fabricate the PCB. This typically involves using a process called photoengraving to create a pattern of conductive traces on the board.

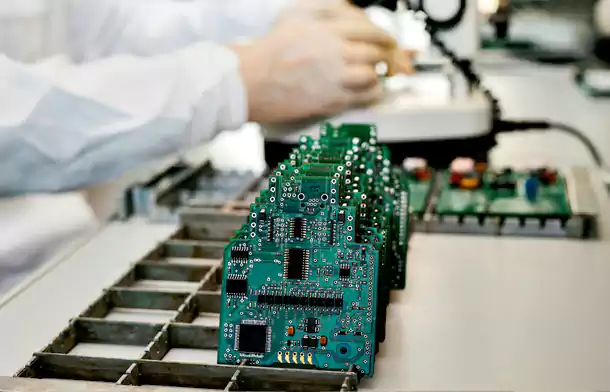

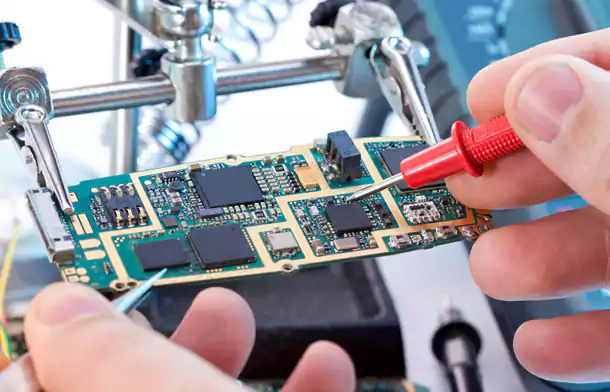

Assembly and testing: Once the PCB is fabricated, the components are assembled onto it, typically using automated pick-and-place machines. The completed board is then tested to ensure that it functions correctly.

We can provide to...

- There are more than 20 design engineers in Suga and 2 more partners to be outsourced

- 90% of the technical staff from PCB design department have more than ten years of industry experience

- Your projects can be finished within 7days for items less than 10layers

- To construct PCB packages for the customer (the customer provides the component DATASHEET).

- To provide customers with PCB impedance calculation, lamination design, QA inspection, process inspection, and EMC inspection.

- Supported PCB software formats include Cadence, Mentor ee, Mentor pads, Altium (99SE), and others.

- After PCB design completed, the fabrication, componnets sourcing and assmebly can be finished all in Suga

Some of the key benefits of DFMA include:

One of the primary benefits of DFMA in construction is the significant reduction of on-site projects due to the use of prefabricated elements.

Reduce assembly costs: DFMA can significantly reduce assembly costs by using fewer parts, requiring less labor, and reducing the number of unique parts.

Start your project from Suga PCB Design Team

From PCB Deisgn to PCB Assembly, We Provide Full Turnkey Electonics Services

Frequently asked questions

What is a PCB?

What is the purpose of a PCB?

What software is used for PCB design?

What are the key design considerations when creating a PCB?

What is the minimum trace width for a PCB?

What is the minimum clearance between traces on a PCB?

What is a gerber file?

What is a BOM?

What is DFM?

What is DFA?

Why Choose Us?

Suga Tech has been providing high-quality PCB&PCBA with fast turnaround times and high customer satisfaction since 2002. We are one of China's largest and most skilled electronics manufacturer.

-

Within 24 hours, prototype orders are processed.

-

It usually takes 5-7 working days to complete some PCB prototypes and small-batch manufacturing.

-

A shorter lead time of 48 hours for small batch production both for PCB and Assembly

-

A complete BOM can be quoted within 1 day if needed

-

Quality issues will be responded within 24 hours and solved within 3 days