Assembly PCB: Bringing Electronics to Life

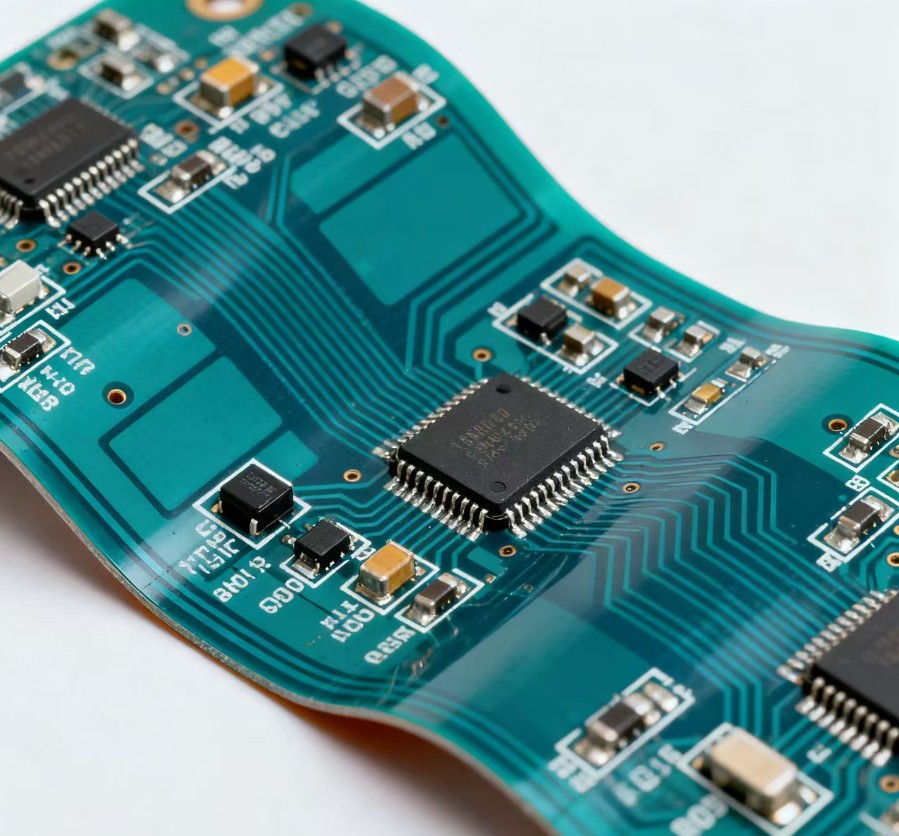

Assembly PCB represents the crucial manufacturing process that transforms bare circuit boards into functional electronic devices. This intricate procedure involves precisely mounting and soldering various electronic components onto a printed circuit board (PCB), ultimately creating the operational heart of countless modern technologies that power our daily lives.

The Essential Steps of Assembly PCB

The assembly PCB process begins with solder paste application. A mechanical stencil precisely deposits solder paste onto the PCB’s contact points. This paste temporarily holds components in position while providing the material that will form permanent electrical connections.

Next, automated placement machines position components with remarkable accuracy. These sophisticated systems read digital design files to place microchips, resistors, capacitors, and other elements exactly where they belong on the board. Modern equipment can position thousands of components per hour while maintaining microscopic precision.

The assembled board then enters a reflow oven where controlled heating melts the solder paste. As the board cools, solid connections form between components and circuit pathways. For boards with components on both sides, or those incorporating different technologies, additional soldering processes may be necessary to ensure complete assembly.

Quality Control in PCB Assembly

Following the assembly process, comprehensive testing ensures reliability. Automated optical inspection systems scan boards for common defects like misplaced components or insufficient solder. For complex components where connections are hidden from view, X-ray inspection verifies solder joint integrity beneath the chips.

Electrical testing represents the final quality assurance step. Technicians perform in-circuit tests to verify proper connections and check for shorts or opens. Functional testing confirms that the assembled PCB performs its intended operations correctly under simulated real-world conditions.

Conclusion

Assembly PCB stands as a fundamental manufacturing discipline that enables modern electronics. Through its carefully orchestrated processes and rigorous quality controls, assembly PCB transforms conceptual designs into the reliable devices we depend on daily. As technology continues advancing, the importance of precise, efficient assembly PCB will only grow, supporting innovation across all electronic sectors from consumer gadgets to industrial equipment and medical devices.