Advantages of Resin-Plugged PCB Boards

Resin-Plugged PCB Boards leverage key technologies including vacuum resin filling and precision impedance matching, delivering exceptional performance in signal quality and environmental adaptability that outperforms solder mask plugging technology. As core circuit boards, they are ideal for high-end uses such as 5G communication and precision instruments.

Resin-Plugged PCB

Resin-Plug PCB | 4oz Heavy Copper | For High-Power Reliability

Table of contents Suga TechI. Core Technology and Application Value

Resin-Plugged PCB Boards are high-end core parts for demanding applications like 5G and precision instruments. They adopt vacuum epoxy resin hole-filling, with impedance test strips (preventing signal interference). And light-sensitive ink (enhancing heat and electrical resistance), suitable for R&D sampling and mass production.

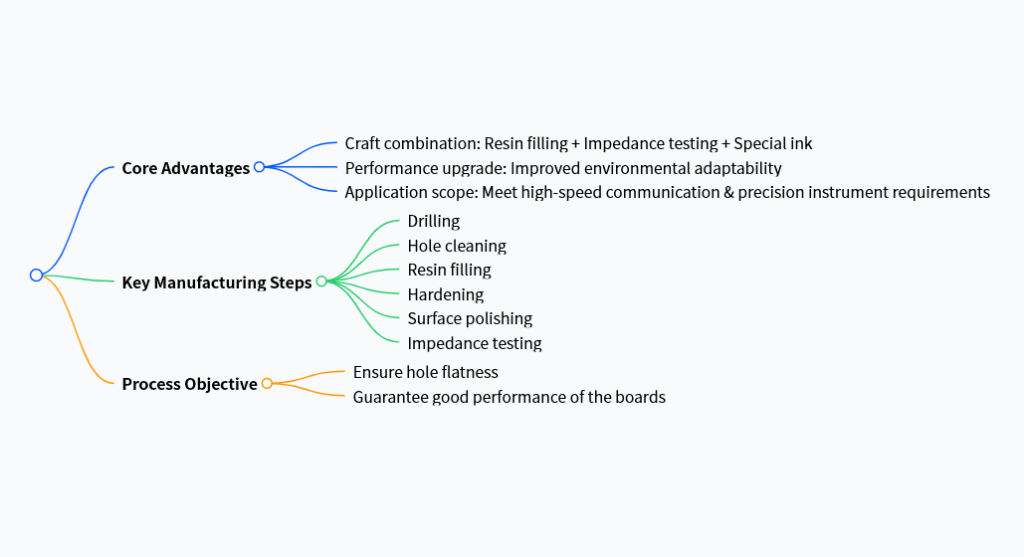

For Resin-Plug PCB Boards, combining resin filling, impedance testing and special ink improves environmental adaptability. It meets high-speed communication and precision instrument requirements.

II. Key Manufacturing Steps

The production of Resin-Plugged PCB Boards follows standard steps:

🔧⚡ Hole Drilling (machine/laser) → 🧪🧹 Chemical Cleaning (decontaminate & remove burrs) → 🫧❌ Resin Filling (full fill, bubble-free) → 🔒✨ Curing & Polishing (flat surface finish) → 📶🔍 Impedance Testing (signal verification)

Standard operations ensure stable production output and consistent quality of Resin-Plug PCB Boards.

III. Main Differences Between Resin Plugging and Solder Mask Plugging

Compared with solder mask plugging, Resin-Plugged PCB Boards have obvious advantages:

IV. Component Packaging Features

In component packaging, Resin-Plug PCB Boards feature small size and high density, with accuracy matching small precision components. Their optimized pin layout reduces signal loss, fitting integrated high-end electronic devices and boosting the competitiveness of Resin-Plug PCB Boards in high-end electronics.

V. Summary

In short, relying on key technologies, Resin-Plug PCB Boards have clear advantages over solder mask plugging in signal quality and environmental adaptability. In addition, standard production ensures their stable output and quality. And meanwhile, precision packaging expands the application scope of Resin Plugged Vias PCB Boards in 5G and precision instruments.

Resin-Plugged PCB Boards show strong competitiveness in R&D response and mass use stability, becoming key parts for high-end electronics. As high-end devices develop towards higher frequency and integration, the application value of Resin Plugged Vias PCB Boards will be more obvious.