Copper-Based PCB: The Thermal Foundation for High-Power Circuits

Copper-based PCB offer a solution. They excel in thermal conductivity. Thus, they become a key thermal management technology, Modern electronics demand high performance. They also are becoming smaller. Heat dissipation is now a key bottleneck. This is especially true in certain fields. These include high-power LED lighting. Power systems and automotive electronics are also included. Traditional FR-4 boards often fail here. They cannot meet the Heat dissipation requirements,Copper-based PCBs offer a solution. They excel in thermal conductivity. Thus, they become a key thermal management technology.

1. What is a Copper-Based PCB?

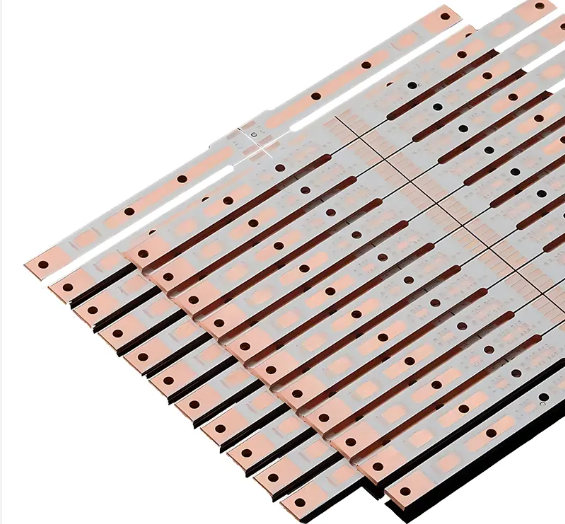

This PCB is a metal-clad circuit board. It is the most representative type. It uses a sandwich structure. From top to bottom, the layers are:

Circuit Layer: It uses electrolytic copper foil. Etching forms the circuits.

Insulation Layer: This is a thermally conductive dielectric. It is also electrically insulating. This is the technical core.

Base Layer: This is the metal substrate. It is a thick copper plate. The thickness is usually 1.0mm to 3.0mm.

This structure is clever. It combines electrical conductivity with thermal conductivity. Heat moves from components quickly. It goes to the metal base layer. Then, it dissipates into the environment. Or, it goes to a heat sink.

2. Key Advantages of Copper-Based PCBs

Their core value is clear. It is shown in these aspects:

Excellent Thermal Conductivity: Copper’s rating is 400 W/(m·K). This is much higher than aluminum. Aluminum is only 200 W/(m·K). FR-4 is about 0.3 W/(m·K). So, it spreads heat fast. This prevents local hot spots.

Good CTE Matching: Copper, ceramic, and silicon chips have close CTE. Thermal stress from cycling is reduced. This improves high-temperature reliability. Product lifespan is also extended.

High Mechanical Strength: The copper base is very sturdy. It does not bend easily. It suits applications needing strong structure.

Superior EMI Shielding: The large copper layer acts as a shield. It helps guard against circuit interference.

3. Wide Range of Applications

Thanks to these strengths, it is the top choice. It is used in many high-end fields:

High-Power LED Lighting: Examples are car headlights. Stage lights and outdoor lighting also use it. It greatly lowers LED junction temperature. This ensures light output and long life.

Power Supply Equipment: Examples are converters and inverters. Industrial power modules use it too. It solves heat for IGBTs and MOSFETs.

Automotive Electronics: It is vital in engine control units. Also in EV motor drivers and battery systems.

RF & Microwave Fields: Some high-power RF amps use it. Base station antennas also need it for stable operation.

Conclusion

In summary, it is not just a simple carrier. It is an active thermal solution. Its unique structure guides and dissipates heat. It offers a solid foundation for high-heat electronics. This ensures their stable operation and long life. Therefore, it is crucial for modern power electronics. It also pushes photoelectronics technology forward.