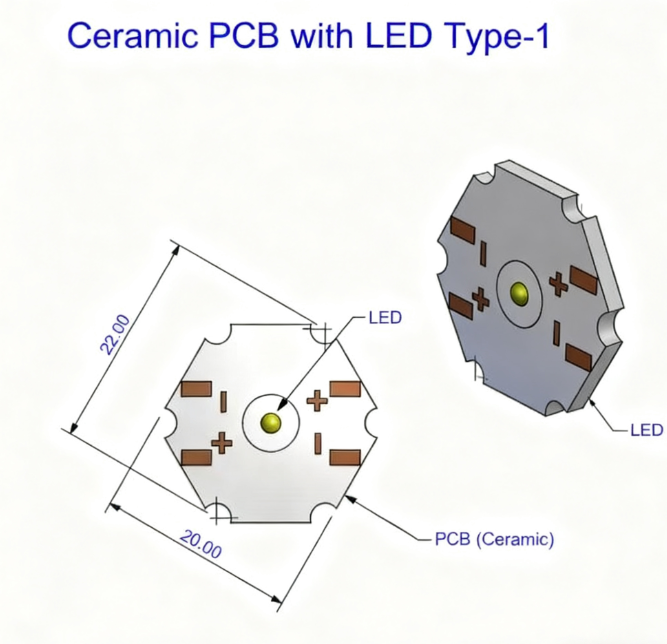

Ceramic PCB with LED: Simple Solution for LED Use in High-Temperature Environments

Ceramic PCB with LED is ideal for high-power LED, laser tech and other high-temp uses,due to great thermal conductivity and heat resistance. This circuit board uses ceramics like alumina, aluminum nitride or silicon carbide as its base. Its heat transfer is much better than old materials like FR4. It solves the heat problem from LED parts working for a long time well, and makes LED modules keep stable brightness and last much longer.

In addition, Ceramic PCB with LED is also good at blocking electricity safely and staying strong mechanically. It can stand up to chemical damage and handle high electrical pressure. Consequently, this makes it great for tight packaging needs like Mini/Micro LEDs. Furthermore, it’s often used in bright LED lighting systems, car LED headlights, laser displays and industrial LED sensors. It shines in semiconductor and LED uses that need both high power and the ability to work in tough environments.

To make Ceramic PCB with LEDs, people use methods like screen printing and thick film tech. These let them put down and process conductive paste accurately on ceramic bases. These methods can make thin conductor lines, allowing more LED chips to be packed closely. This helps next-gen LED products become smaller and more integrated. It’s worth mentioning that at the 27th China Hi-Tech Fair (CHTF), held at Shenzhen World Exhibition & Convention Center (Bao’an) from November 14 to 16, 2025. The Information Technology and Products Exhibition will show Ceramic PCB with LEDs technology as one of the key highlights in its Semiconductor Area.

Common questions about Ceramic PCB with LED are as follows:

1.What is a Ceramic PCB with LED, and what is it used for?

A Ceramic PCB with LED is a ceramic circuit board made for LED parts, using alumina (Al₂O₃) or aluminum nitride (AlN) as its base. It can handle very high heat and transfers heat well. It’s used in LED situations that need high power, heat resistance and reliability—like bright LED lights and car LED modules.

2.Compared with FR4 or IMS PCBs, what advantages does a Ceramic PCB with LED have in LED uses?

For LEDs, Ceramic PCB with LED transfers heat better (aluminum nitride bases can reach 170W/m·K) and matches the way materials expand with heat better. This lowers the temperature of LED chips and reduces light fading. It also resists environmental damage well, making LED products more durable in tough conditions like high heat or humidity.

3.What materials do manufacturers use to make Ceramic PCBs with LEDs, and which is best for LEDs?

Common materials are alumina (Al₂O₃) and aluminum nitride (AlN). Specifically, aluminum nitride transfers heat better, so it’s great for high-power LED modules. On the other hand, alumina balances cost and performance, making it good for medium-power LED lights. Both meet the insulation and heat transfer needs of LED packaging.

4.Which LED uses are Ceramic PCB with LEDs most suitable for?

We often use it in bright LED street lights, car LED headlights, Mini/Micro LED displays, medical LED endoscopes and industrial LED inspection tools. Any LED use where heat builds up a lot and power is high will benefit from Ceramic PCB with LED.

5.What production plans for Ceramic PCBs with LEDs will exhibitors show at the 2025 Shenzhen Hi-Tech Fair?

At the Semiconductor Area of the Information Technology and Products Exhibition of the 27th CHTF (Shenzhen World Exhibition & Convention Center · Bao’an) from November 14 to 16, 2025. Many companies will show Ceramic PCB with LEDs solutions. These include aluminum nitride/alumina base products of different thicknesses, LED packaging bases with thin conductor structures, and high-quality surface treatments like electroless nickel-gold plating and silver plating. You can see live tests comparing LED module heat transfer on site. And ask about custom samples and mass production services.

6.How does Ceramic PCB with LEDs help LEDs dissipate heat well?

Ceramic bases like aluminum nitride can act as direct heat paths. Heat moves quickly from the base to the outside, so you don’t need extra heat sinks most of the time. Additionally, this all-in-one heat dissipation design reduces the weight of LED products and lowers their cooling costs—making it perfect for LED applications with limited space.

7.What challenges come with making Ceramic PCB with LEDs for LED uses?

To pack LEDs closely, makers face challenges like making very thin conductor lines (to fit Mini LED chip spacing), drilling small, accurate holes in ceramic bases (for LED pins) and making sure the whole board transfers heat evenly—so no local LED chips overheat. Suga has fixed these problems by improving thick film printing.

8.What extra services does Suga offer for Ceramic PCB with LEDs?

Besides production, Suga also provides assembly, electrical testing, Automated Optical Inspection (AOI) and full component assembly. It’s a one-stop service with reliable, on-time delivery.