Why must one choose SMT Assembly services?

SMT Assembly services represent a crucial direction for the transformation of Chinese factories. This is largely attributed to the booming global electronics manufacturing industry and the upgrading demands of the Chinese manufacturing sector. As electronic products become smaller and more high-performance, surface mount technology (SMT), as the core process of electronic assembly, can efficiently achieve high-density mounting of components, enhancing production efficiency and product quality. Chinese factories, leveraging their well-established supply chains, cost advantages, and policy support, are actively embracing this trend to strengthen their international competitiveness. The following analysis explores the driving forces behind this transformation from two key aspects.

The market demand and technical advantages of SMT Assembly services

The rise of SMT Assembly services originated from the strong global demand for electronic devices. The rapid expansion of industries such as smart phones, Internet of Things devices, and automotive electronics has driven the reliance on SMT technology, as this technology can support the production of miniaturized and highly reliable circuit boards. As China is the world’s factory with a vast manufacturing base, factories that transform to provide SMT Assembly services can seize the growth opportunities of export orders while meeting the domestic demand for consumption upgrade. Furthermore, after the outbreak of COVID-19, remote working and digitalization accelerated, which further stimulated the demand for localizing the electronic supply chain, prompting factories to invest in SMT production lines in order to shorten the delivery cycle. This transformation not only enhances the added value of the factories but also helps them transition from low-end processing to high-end manufacturing, achieving sustainable development.

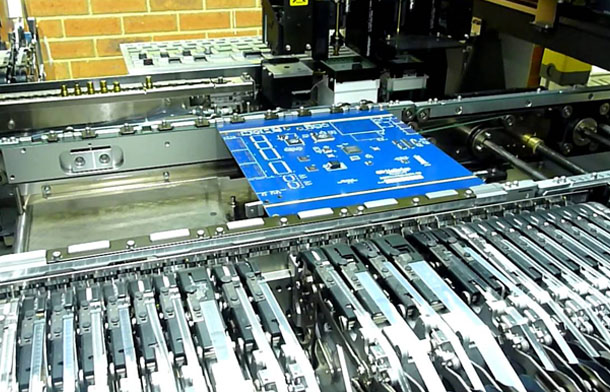

The popularity of SMT Assembly services is also attributed to its significant technical advantages, such as high precision and automation. The SMT technology enables the rapid and accurate placement of components through surface mount machines, significantly reducing human errors and improving production consistency and yield. Under the guidance of the government’s “Intelligent Manufacturing” policy, Chinese factories have actively introduced advanced equipment such as robots and AI quality inspection to reduce production costs while enhancing flexibility. For instance, SMT production lines can accommodate multiple product varieties and small batch orders, adapting to the trend of personalized markets. Moreover, the SMT process is more energy-efficient and environmentally friendly compared to traditional mounting technology, conforming to global green manufacturing standards, which helps Chinese factories break through international trade barriers and expand into high-end markets. Through transformation, factories not only optimize resource allocation but also enhance the synergy effect of the industrial chain.

Summary

In conclusion, the transformation of Chinese factories to provide SMT Assembly services is the result of the combined effect of market pull and technological push. This trend will continue and deepen China’s dominant position in global electronic manufacturing.