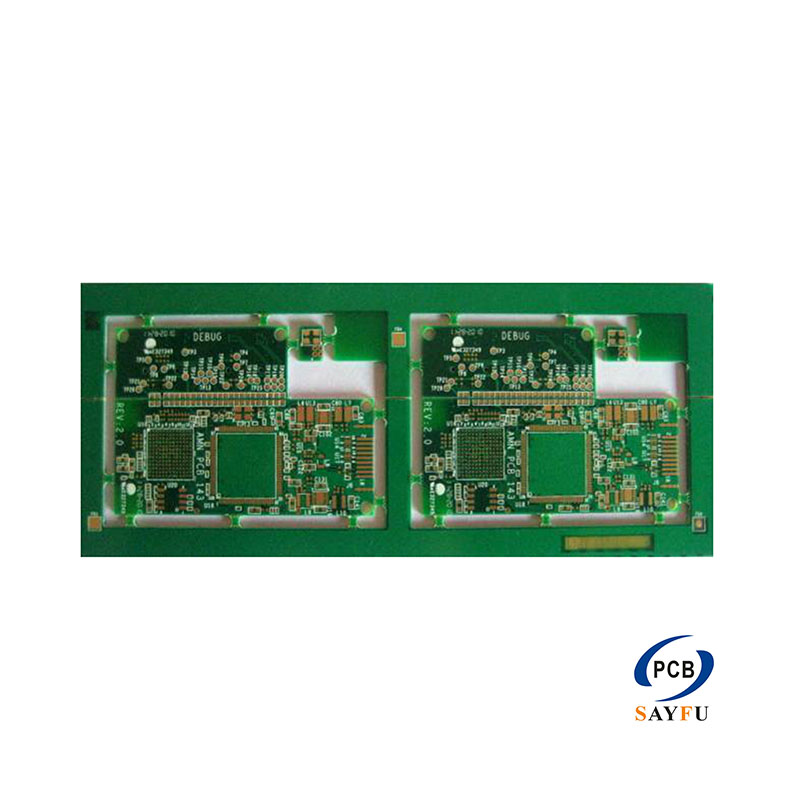

SMT Challenges and Solutions for HDI Boards

Precision Processes for Next-Generation SMT for HDI boards

SMT for HDI boards are essential for modern electronics, pushing the limits of miniaturization.

However, their complex design introduces significant challenges for SMT assembly, demanding specialized process optimization

Firstly, the ultra-fine pitch and dense component placement severely test solder paste printing. Using ultra-thin stencils (e.g., 100µm or less)

and Type 6 or finer powder solder paste is crucial to prevent bridging and ensure sufficient volume for micro-BGAs and 01005 components.

Subsequently, SMT for HDI boards component placement requires extreme accuracy.

High-precision vision systems and calibrated pick-and-place machines are mandatory to achieve proper alignment on densely packed pads.

Furthermore, the thermal management during reflow soldering is critical. The complex,

multi-layer stack-up of HDI boards can create uneven thermal mass, leading to hot or cold spots.

A carefully profiled oven recipe is vital to avoid defects like tombstoning or voids while ensuring reliable connections for blind and buried vias.

Finally, inspection becomes even more critical. Standard AOI may struggle with hidden joints. Therefore,

3D AOI and X-ray inspection (AXI) are indispensable for verifying solder quality under components and checking for micro-voids or cracks in vias.

In conclusion, successfully assembling HDI boards requires a tightly controlled process,

from precise printing and accurate placement to optimized reflow and rigorous inspection, ensuring high yield and reliability.

Moreover, as HDI technology continues to evolve, manufacturers are increasingly adopting advanced materials such as low-loss substrates and laser-drillable dielectrics to further enhance signal integrity and thermal performance.

Embracing these innovations, alongside continuous process monitoring and adaptive feedback systems,

will be key to overcoming future miniaturization hurdles and maintaining production excellence in advanced PCB manufacturing.

To address these evolving demands, investing in cutting-edge equipment and continuous operator training becomes indispensable. Implementing real-time process controls and leveraging data analytics can further optimize production efficiency and defect detection, ensuring robust HDI board performance in increasingly demanding applications.