RF PCBA High-Frequency: Technical Analysis and Future Prospects

RF PCBA high-frequency for Technical analysis and application prospects is the core carrier for signal transmission

1. RF PCBA as the Core Carrier for Signal Transmission

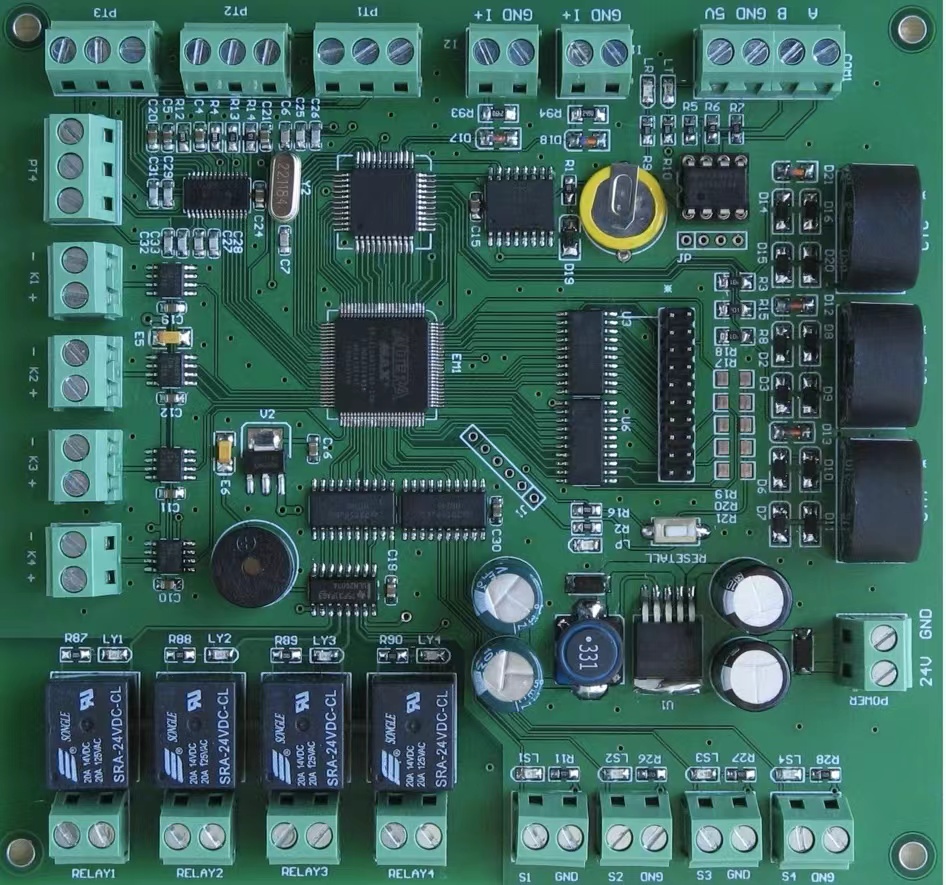

RF Printed Circuit Board Assemblies (PCBAs) are critical for high-frequency signal transmission in modern communication systems, including 5G, satellite navigation, and radar systems. then their performance directly determines the quality, stability, and efficiency of the entire system. As wireless communication evolves toward higher frequencies and speeds,However, RF PCBA design and manufacturing face unprecedented challenges and innovation opportunities.

2. Material Technology Breakthroughs

Modern high-frequency RF PCBAs rely on advanced materials to overcome limitations of traditional FR-4 substrates. Key innovations include as below

Low-Loss Dielectric Materials:

Firstly Rogers RO4000 Series: Optimized for millimeter-wave (mmWave) applications with stable dielectric constants (Dk) and low loss tangent (Df).

Secondly Taconic RF-35: High-frequency laminates with consistent Dk across temperature ranges.

Performance Gains:

In military phased array radar projects, then PTFE substrates reduced insertion loss by 40% in the Ka-band (30–300 GHz).

3. RF PCBA Testing and Quality Assurance

Traditional contact-probe testing is insufficient for frequencies above 100 GHz. New methods include:

n addition,Non-Contact Terahertz Imaging: Resolves internal PCB defects at micron-level precision.

AI-Driven Automated Testing:

So automotive radar manufacturers report 300% efficiency gains and 99.97% defect detection rates for 77 GHz mmWave circuits.

4. Market Outlook and Future Trends

Market Growth:

Yole predicts the global high-frequency RF PCBA market will exceed $8.2 billion by 2025, and growing at a CAGR of 11.3% (2023 data).

Frontier Applications:

6G Pre-Research: Focus on terahertz (THz) frequency bands and photonic integration.

so we can see Quantum Communication: RF PCBA integration with photonic chips for ultra-low-loss signal transmission.

5. Challenges and Risks

Data Limitations: Some case studies (e.g., military radar projects) lack peer-reviewed validation.

Material Costs: Advanced substrates like Rogers RO4000 remain expensive compared to FR-4.

Regulatory Uncertainty: THz and quantum communication standards are still evolving.

6. Conclusion

RF PCBA technology is pivotal for next-generation communication systems. so With advancements in materials, design, and testing, it will enable broader spectrum utilization and support innovations like 6G and quantum networks. However, cost, scalability, and regulatory alignment remain critical hurdles.