PCB Assembly&Electronic Manufacturing Service-Suga

PCB Assembly&Electronic Manufacturing Service -Suga Company has been doing for the past 33 years.

PCB Assembly&Electronic Manufacturing Service are one of Suga’s distinctive features.

Suga has two factories, one in China and the other in Vietnam. In addition, to facilitate customer service, Set up four offices, located respectively in Shenzhen, the United States, Ireland and Japan.

Suga not only provides PCB Assembly. We can also provide customers various types of PCBS, such as HDI,Heavy coppre PCB,Rigid-Flex PCB,Aluminum PCB, etc., and purchase various components to provide one-stop services for customers.

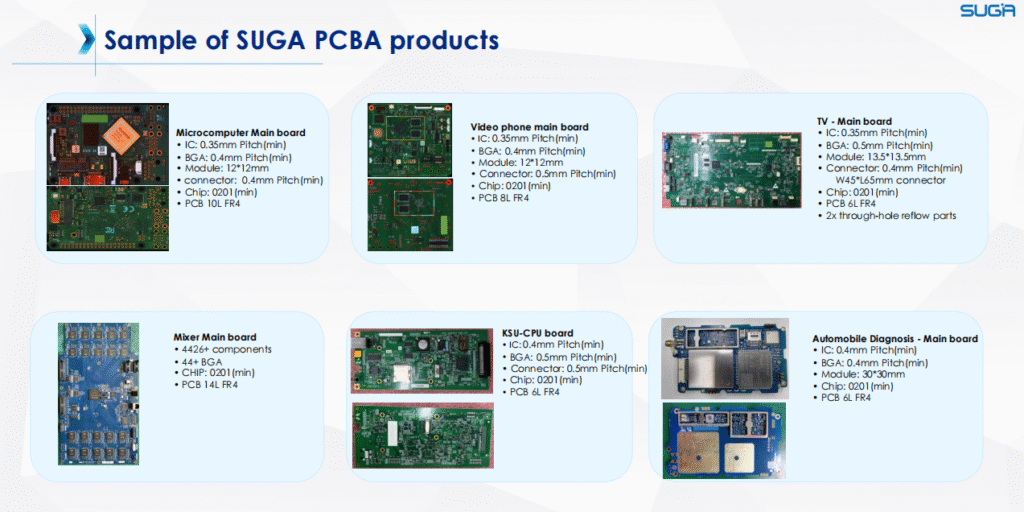

In the PCBA industry, Suga can be regarded as a leader among peers. The product covers not only the fields of medical, automotive, industrial control, but also military industry and consumer audio., and providing satisfactory services to high-quality customers.

We have a total of 21 SMT lines. Among them, there are 15 lines in the Dongguan factory and 6 lines in the Vietnam factory. Additionally, there are 22 PCBA lines, with 18 lines in the Dongguan factory and 4 lines in the Vietnam factory. There are also over 70 assembly lines, which can meet any requirements of our customers.

Order & logistic Flow for PCB Assembly&Electronic Manufacturing Service

Dongguan orders:

Customer places an order➡Chinese factories/offices receive orders➡Engineer support/Material purchase/Production/Planning/Shipment booking➡Directly ship to end-customer.

VN orders:

Customer places an order➡Chinese factories/offices receive orders➡Engineer support/Material purchase➡Guangdong/HK warehouse➡Air/land transportation to VN factory➡/Production/Planning/Shipment booking➡Directly ship to end-customer.

Remarks: Need advance approximately 2wks to receive materials in CH/HK if produce in VN. Direct ship from VN seaport to end-customer.Additionally,We usually arrange sea shipment for all materials from China/HK to VN and total transit LT is around 8-10 days.

Suga core advantages lie in its complete and efficient supply chain, mature and reliable manufacturing technology, advanced equipment, and rapid response to volume-produce. Therefore, the combination of these four main advantages provides you with a highly competitive one-stop manufacturing solution, making it a wise choice that is efficient, reliable and cost-effective.