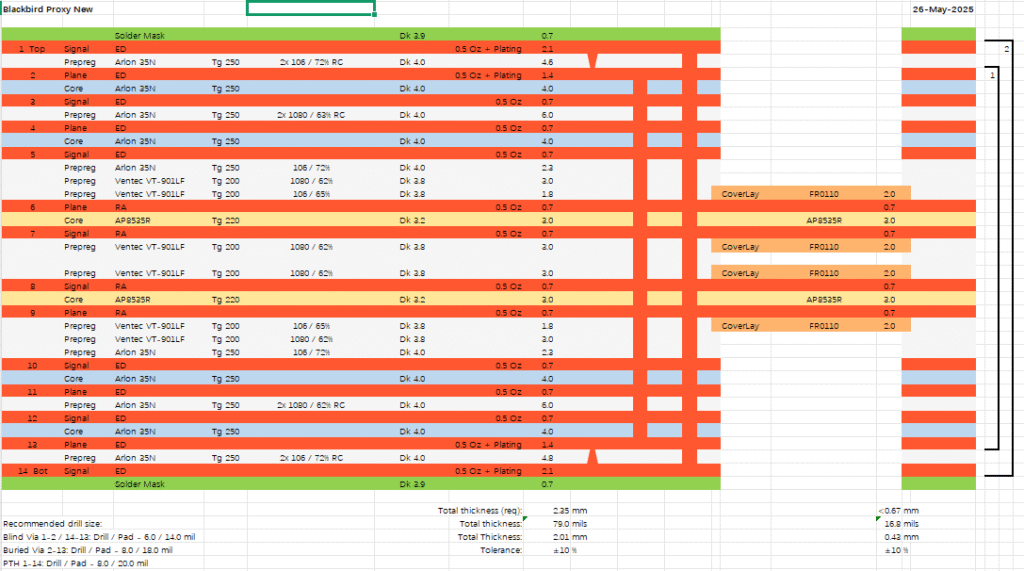

14L HDI with Rigid+Flex design:High density interconnect technology

14L HDI with Rigid+Flex :as an advanced PCB solution, it is emerging as a key technology in high-end consumer electronics, medical devices, aerospace, and industrial automation.

What is 14L HDI with Rigid+Flex design?

-14L HDI (high-density interconnect):

Compared with traditional multi-layer PCBs, HDI technology achieves higher wiring density and shorter signal paths through finer line width/spacing (usually ≤ 100 μ m), micro holes (laser drilling), and stacked blind buried hole designs, thereby improving circuit performance and reducing electromagnetic interference (EMI).

-1n1 (arbitrary layer interconnection):

The 1n1 technology allows direct interconnection between any layer of the PCB without relying on traditional via designs. This flexibility significantly improves signal transmission efficiency, especially suitable for high-frequency, high-speed signal application scenarios (such as 5G communication, AI acceleration cards, etc.).

-Rigid+Flex:

By integrating rigid PCB and flexible circuit (FPC) into the same design, Rigid+Flex technology can achieve complex wiring in three-dimensional space while balancing mechanical strength and bendability. For example, foldable screen phones, wearable devices, and drone camera modules all rely on such designs.

Analysis of Technical Advantages

(1) Performance improvement

Signal integrity:

The 1n1 interconnect shortens the transmission path of critical signals such as PCIe 5.0 and DDR5, reducing latency and power consumption.

High frequency support:

HDI microporous technology reduces parasitic capacitance/inductance and is suitable for high-frequency applications such as millimeter wave radar and Wi Fi 7.

(2) Space optimization

By using high-density wiring and a combination of rigid and flexible design, the PCB volume can be reduced by 30% to 50%, helping to make devices thinner and lighter (such as AR/VR glasses).

(3) Reliability enhancement

The Rigid+Flex structure can withstand mechanical vibrations and thermal cycling impacts, making it suitable for automotive electronics (such as ADAS sensors) and industrial robots.

14L HDI with Rigid+Flex Application scenarios

-Consumer electronics folding screen mobile phone hinge circuit, TWS headphone charging case motherboard

-Medical equipment endoscope imaging module, implantable sensor

-Aerospace satellite communication module, unmanned aerial vehicle flight control system

-Automotive electronic intelligent cockpit display screen, battery management system (BMS)

Future Trends and Challenges

-Material Innovation:

Low loss dielectric materials, such as modified polyimide, will further enhance high-frequency performance.

-Manufacturing process:

3D printed PCBs and AI assisted wiring design are expected to break through existing technological bottlenecks.

-Cost control:

At present, the manufacturing cost of 14L HDI 1n1 is relatively high, and the threshold needs to be lowered through large-scale production.