PCB Assembly Manufacturer: Choosing the Right Partner

PCB Assembly Manufacturer is Your Trusted Partner-Suga

PCB assembly manufacturer is very important in the fast-paced global electronics landscape. We have to use the expertise in PCBA technology because of the need of quality assurance and supply chain management.

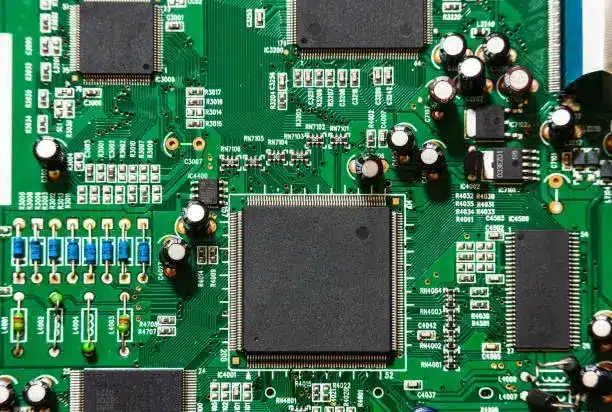

PCB Assembly Manufacturer

Technical Capabilities

Firstly,advanced technology and equipment form the cornerstone of PCBA excellence. Then,Prioritize manufacturers specializing in High-Density Interconnect (HDI) technology, leveraging laser drilling and any-layer interconnections to meet stringent demands of 5G communications, AI chips, and IoT devices.

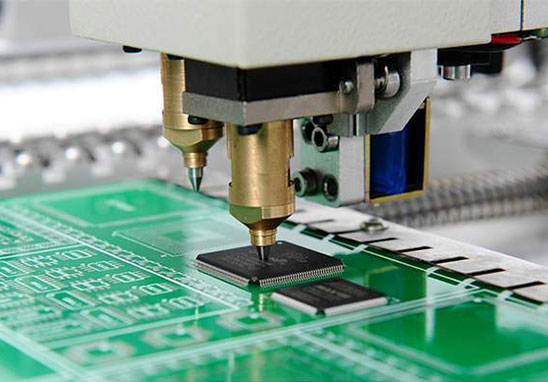

As illustrated in the image of the precision placement machine (e.g., Fuji CP/FX series), top-tier providers excel in:

- SMT precision: Placement of 01005 micro-components and 0.3mm pitch BGA packages with ±15μm accuracy.

- Complex circuitry: Implementation of blind/buried vias, impedance control (±5% tolerance), and multi-layer PCB assemblies (up to 20 layers).

- Hybrid processes: Integration of SMT, through-hole (DIP), and mixed-technology assembly for ruggedized PCBA.

Note:Surface Mount Technology (SMT) in Electronics Manufacturing

Surface Mount Technology (SMT) is a particularly crucial process in electronic manufacturing. It is to mount electronic components onto the surface of a printed circuit board (PCB). Firstly, the equipment precisely picks up the components. Then, after ensuring accurate positioning via optical methods and other steps, components are firmly soldered onto PCB pads using reflow and wave soldering techniques.

However,compared with traditional assembly techniques, SMT can achieve miniaturization of electronic products, boost production efficiency, and enhance circuit performance. It is widely applied in manufacturing smartphones, computers, and other electronics, driving the electronics industry toward miniaturization and high-density integration.

Quality Assurance System

Quality certifications are non-negotiable for mission-critical PCBA. Opt for manufacturers with:

- ISO 9001, IATF 16949 (automotive), ISO 13485 (medical) accreditations.

- Multi-tier inspection: Initial, in-process, and final checks using AOI (Automated Optical Inspection), AXI (X-ray Imaging), and IPC-610 Class 3 compliance.

- Reliability testing: Temperature cycling (-40°C to +125°C), humidity resistance (85% RH), and vibration analysis to ensure (solder joint reliability).

Supply Chain ManagementPCB Assembly Manufacturer

A robust supply chain is vital for PCBA continuity. Evaluate partners who:

- Firstly,Maintain VMI (Vendor-Managed Inventory) and JIT (Just-In-Time) delivery systems.

- Secondly,Offer qualified alternate components (QAC) libraries to mitigate material shortages (response time ≤24 hours).

- Thirdly,Optimize MOQ (Minimum Order Quantity) policies (e.g., 50-100 units for prototyping, scalable to 100K+ for mass production).PCB Assembly Contract Manufacturer

Cost Optimization Solutions

Strategic PCBA cost management involves:

- DFM/DFA (Design for Manufacturability/Assembly) reviews to reduce rework (e.g., PCB panelization for 15% cost savings).

- Value engineering (VE) for component substitution (e.g., equivalent passive components with 20% cost reduction).

- Furthermore,Tiered pricing models: Volume discounts for orders exceeding 5,000 units, with transparent cost breakdowns (material/labor/overhead).

Full-cycle Technical Support

In the fast-paced PCBA sector, agility is key:

- DFM feedback within 24 hours, prototyping in 72 hours (HDI prototypes within 5 days).

- 24/7 technical support: On-site troubleshooting for process issues (e.g., solder bridging, component misalignment).

- Post-production services: Warranty coverage, product lifecycle management, and EOL (End-of-Life) component sourcing.

In conclusion,selecting a PCBA partner requires balancing technical depth, quality rigor, and supply chain agility. So By prioritizing these factors, businesses can secure reliable partners for everything from rapid-prototyping to high-volume PCB assembly, ensuring competitive edge in global markets.