Assembly technology process

The Micro-Scale Mastery of SMT Assembly Technology

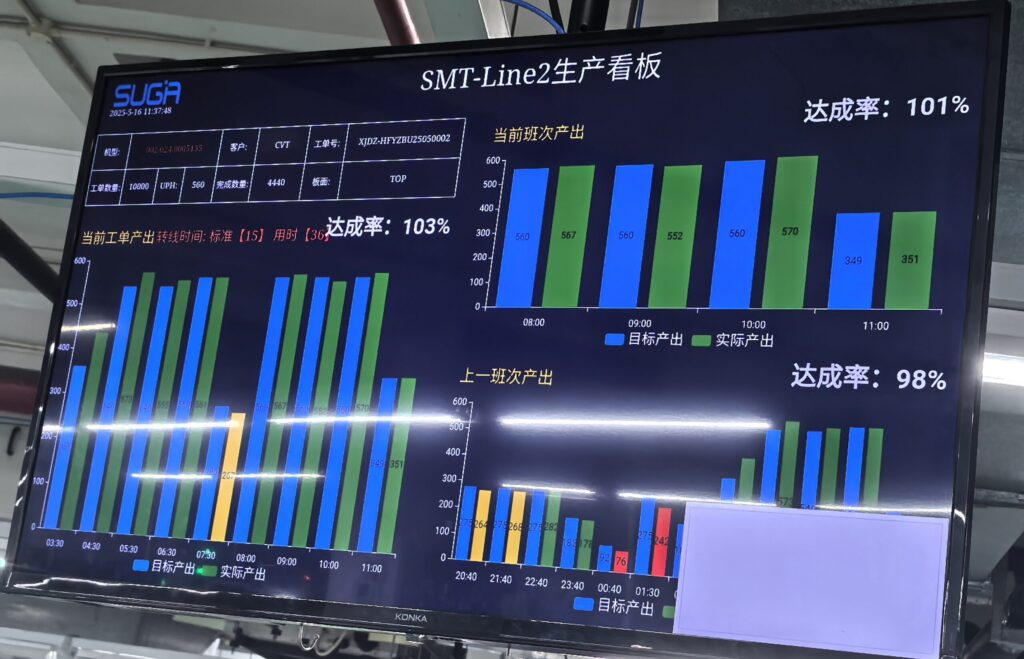

We can see assembly technology process In the filed of electronic manufacturing. PCB assemble like a micron level precise dance. Put hundreds of micro components to assemble on the curcuit board with exacting accuracy, during this high automotive production process,

condensed into intelligence of modern manufacturing.

Firstly: Prelude Process Preparation for assembly technology process.

The SMT process begins strict preparation of material. SMT line verifies the Bom list first, use optical test equipment to scan PCB pads with micron level.

to insure solder mask thinckness control within 15-25μm. Meanwhile, the stencil printing apertures are Opening a hole based on the components space,

0402 footprint components require stencil thickness to be accurate 0.1mm level.

Secondly, Core process precision placement for assembly technology process.

Then Fully automatic pick and place machine run with the speed of 20 components per second,

high precision machine repeat placement achieve ±25μm,

double rail SMT line use vision placement system,

in fact, through CCD camera to capture mark Coordinate to compensate displacement causing by PCB thermal deformation. As for special packages like QFN, the equipment will start 3D laser inspection module.

Insure pin Coplanarity error no more than 0.05mm.

Thirdly:Inspection art for assembly technology process Reflow soldering for Assembly technology process

AOI inspection will scan the solder point at the resolution of 0.01mm/pixel, and Algorithm can identify 27 defects like Tombstone effect,

Seok-joo inside, the latest 3D SPI system can measure solder paste shape,

achieving±1μm for inspection 0201 components solder joint detection accuracy, ensuring welding reliability.

Precision equipment powers this production system, achieving the highest standards in modern electronics manufacturing. From medical devices to aerospace instruments, advanced SMT processes guarantee stable performance across diverse electronic applications. As 5G technology evolves and components shrink to microscopic scales, in order to SMT continues to push boundaries in ultra-precision assembly.